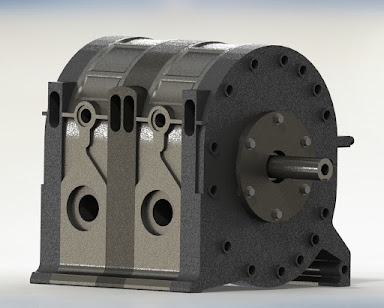

VAWT

The design was made using solidworks and calculations were done using python.A vertical axis wind turbine (VAWT) has blades mounted on the top of the main shaft structure, rather than in the front like an aircraft rotor. The generator is usually placed at the tower base. Used less often than their horizontal counterparts, VAWTs are more practical in residential areas.

VAWT Advantages

These turbines have fewer parts than those that orient the

rotary mechanism and blades horizontally. That means fewer components to wear

out and break down. Also, the supporting strength of the tower doesn’t need to

be as much, because the gearbox and generator are near the ground. Parts for

controlling pitch and yaw aren’t needed either.

Disadvantages of VAWTs

Not all of the blades produce torque at the same time, which

limits the efficiency of vertical systems in producing energy. Other blades are

simply pushed along. There is also more drag on the blades when they rotate.

Although a turbine can work in gusty winds, that is not always the case; the

low starting torque and dynamic stability problems can limit functionality in

conditions the turbine wasn’t specifically designed for.

Calculations:

Material Selection:

|

Material |

Tensile

strength (in Mpa) |

Weight (Kg) |

|

FRP |

34.5-104 |

1.558 |

|

FRE |

55-130 |

1.7 |

|

GFRP |

483–4580 |

1.771 |

|

AFRP |

1720–3620 |

2.054 |

|

CFRP |

600–3920 |

2.125 |

|

BFRP |

600–1500 |

2.691 |

|

Steel |

483–690 |

11.119 |

Power output:

|

Potential wind power |

1066.46 W |

|

Power output of wind turbine |

275.329 W |

|

Torque required |

17.537 N-m |

|

Lift force acting on rotor |

107.378 N |

|

Drag force acting on rotor |

63.326 N |

|

Stress acting on the rotor |

3.005 Mpa |

Project Link

Comments

Post a Comment